This is my Harrisville rug loom. I don't know anyone else who weaves tapestry on one, but I would like to recommend it as a fantastic tapestry loom.

I love one feature of the Harrisville rug loom especially. The warp extender. This ingenious little addition to the countermarche loom keeps the tension even throughout the piece. The tension is superb both because it is a big floor loom with a worm gear and because of this warp extender. The warp extender allows me to raise the warp away from the warp beam as far as I need to for the piece I am going to weave.

When the warp threads are wrapped around and around a back beam, they fall in between each other and the tension in my experience is never even when you start advancing. Even if you are one of the million-stick-club and you are very meticulous about winding your warp with sticks, things can go awry easily. The warp extender pulls all the threads up evenly around a smooth steel tube. You start your tapestry with the extender raised, tie on and get everything even, and then as you weave and pull the piece forward, instead of unwinding the warp beam, you lower the extender. Genius.

And of course it is a countermarche loom and I love the fact that the warp threads get pulled evenly from either direction on each shed. I like things even. Perhaps it is a good thing for tapestry or perhaps I just have a touch of OCD.

This picture is looking from the front of the loom toward the back with the warp extender raised.

This picture is from the back of the loom looking at the raised warp and the warp beam.

Incidentally, I never warp sectionally even though both my floor looms have sectional beams. If I knew I was going to use a fairly consistent warp width on this loom, I might consider it just to get a lot of yards on at once. But I find sectional warping picky and not actually that great a method if you're looking for a very even warp. (I felt guilty about not warping sectionally for a long time--I have the spool rack and the tension box and the little counter to count yards, but I finally reached a place where I decided I could do things my own way and didn't have to listen to all the old teachers voices echoing in my head. My head is much quieter now.) I usually just put on enough warp for a couple tapestries, which, after all, are going to take many months to finish... and by the end of all that I'm probably going to want to try something different anyway.

Tuesday, April 30, 2013

Sunday, April 28, 2013

The Great Dye Experiment of 2013, Part 2

I dye my own tapestry yarn. And I dye yarn for my students to use in my classes. And sometimes I even sell it to them. I posted a little bit a few months ago about some dye projects gone bad.

A bad dye job

and

The Great Dye Experiment of 2013, Part 1

This weekend was my first dye run in my new place... the dye studio residing in my garage now. I took some good advice from my expert dyer friend Cornelia Theimer Gardella and watched the pH of my pots much closer. I usually just dump in enough citric acid to drop the pH all the way to 3.5 and call it good. But I think sometimes that makes the dye hit too hard (and Conni was sure of it, so I decided to listen to her). So this time I used much less acid and monitored the pH. The results were excellent. Even the light colors which are always the most difficult to level turned out great.

Here are the oranges I dyed in March which were so bad.

And here are the ones I just dyed.

The first batch will be overdyed and turned into something lovely.

My biggest question for all of you out there who dye in various parts of the world is, did the water have anything to do with this difference?

The water I was using in Alamosa, CO was well water with large amounts of minerals in it and no water softener. The water I used in Velarde, NM before that was also well water but I had a water softener and had less trouble getting even dyeing than I did in Alamosa. Now I am on Santa Fe city water and I would bet there are still a lot of minerals in the water, this being NM and all, but as far as I know, there is no water softener in this house...

Does the water make a difference in how the dye takes up and how even it is? Have any of you had this experience?

(I'm using Lanaset/Sabraset acid wool dyes and dying Harrisville-milled wool.)

Not a bad days work though... nice, even, hand-dyed yarn ready for another workshop.

A bad dye job

and

The Great Dye Experiment of 2013, Part 1

This weekend was my first dye run in my new place... the dye studio residing in my garage now. I took some good advice from my expert dyer friend Cornelia Theimer Gardella and watched the pH of my pots much closer. I usually just dump in enough citric acid to drop the pH all the way to 3.5 and call it good. But I think sometimes that makes the dye hit too hard (and Conni was sure of it, so I decided to listen to her). So this time I used much less acid and monitored the pH. The results were excellent. Even the light colors which are always the most difficult to level turned out great.

Here are the oranges I dyed in March which were so bad.

And here are the ones I just dyed.

The first batch will be overdyed and turned into something lovely.

My biggest question for all of you out there who dye in various parts of the world is, did the water have anything to do with this difference?

The water I was using in Alamosa, CO was well water with large amounts of minerals in it and no water softener. The water I used in Velarde, NM before that was also well water but I had a water softener and had less trouble getting even dyeing than I did in Alamosa. Now I am on Santa Fe city water and I would bet there are still a lot of minerals in the water, this being NM and all, but as far as I know, there is no water softener in this house...

Does the water make a difference in how the dye takes up and how even it is? Have any of you had this experience?

(I'm using Lanaset/Sabraset acid wool dyes and dying Harrisville-milled wool.)

Not a bad days work though... nice, even, hand-dyed yarn ready for another workshop.

Friday, April 26, 2013

Color Gradation Tapestry Class in Santa Fe!

In case you missed the announcement, I am teaching Color Gradation Techniques for Tapestry May 4, 5, and 7 in my studio in Santa Fe and I still have a two open slots. The new studio is shaping up and I am excited to actually teach students in a place where I have all my supplies, books, and equipment accessible. So come and join us for a really fun class.

Here is the post with more information about the class. CLICK HERE.

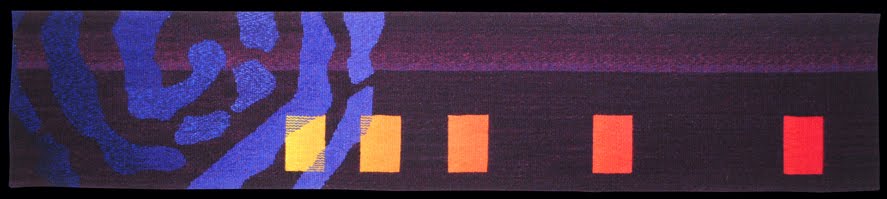

We'll learn to turn a mess like this

Into something like this!

...but perhaps not in 3 days.

Santa Fe Creative Tourism post about the class is HERE.

Here is the post with more information about the class. CLICK HERE.

We'll learn to turn a mess like this

Into something like this!

...but perhaps not in 3 days.

Santa Fe Creative Tourism post about the class is HERE.

Thursday, April 25, 2013

Fiber Art Now, Spring 2013

I was happy have a very small contribution to the Spring 2013 issue of Fiber Art Now. The question was, "How does your environment impact your artistic process?"

I happened to be driving through Pueblo, CO this weekend which has a Barnes & Noble right off the freeway. I knew that Fiber Art Now was carried on the B&N newsstand and pulled over to get an extra copy. I started scanning the crafting magazines for it--you know, the spot where you find 25 knitting magazines, Handwoven, and the magazines with photos of beautiful studios and/or scrapbooks. And I didn't see it and I jumped right to the conclusion that this particular B&N didn't carry it, and then I thought, well maybe they sold out! And then I looked a little farther to my right. And there it was with the art magazines. Right where it should be.

I happened to be driving through Pueblo, CO this weekend which has a Barnes & Noble right off the freeway. I knew that Fiber Art Now was carried on the B&N newsstand and pulled over to get an extra copy. I started scanning the crafting magazines for it--you know, the spot where you find 25 knitting magazines, Handwoven, and the magazines with photos of beautiful studios and/or scrapbooks. And I didn't see it and I jumped right to the conclusion that this particular B&N didn't carry it, and then I thought, well maybe they sold out! And then I looked a little farther to my right. And there it was with the art magazines. Right where it should be.

Tuesday, April 23, 2013

Taos Fiber Marketplace, a brief recap

I did demonstrate at Taos Fiber Marketplace on Saturday at the Taos Convention Center. It was not a lovely day and Taos was not flooded with crowds of people enjoying the sunshine. In fact, at one point it was snowing. But I did meet many amazing people, most of whom were vendors or artists, and I enjoyed my time there. And I was pleased to have a couple potential students and people interested in my work come and search me out specifically.

Here are a few photos from the weekend. And of course I did a lot more talking than weaving, so little progress was made on the Mirrix.

This is Bettye Sullivan and the rugs she and her husband Alex make.

I was rather unreasonably excited about this idea. This is Margaret Sunday's flower hammer being held up by magnets. Look at all the tools you can keep track of with an idea like this. I'll be looking for those magnets. Thanks Margaret!

Here are a few photos from the weekend. And of course I did a lot more talking than weaving, so little progress was made on the Mirrix.

I bought some more tools from Jim Hokett of Hokett Would Work. He makes amazing weaving tools in his workshop in Magdalena, NM. I have not used a boat shuttle for years, but he had some very tiny ones made for using that little bit of warp you want to fill at the end of your project. I never have that problem with tapestry, but I do have trouble with the warp-as-weft sections I use in my headers especially on the Mirrix. The bobbins I have the warp wound on are difficult to get through the narrow Mirrix warp. One of Jim's shuttles was perfect! And it is gorgeous.

This is Bettye Sullivan and the rugs she and her husband Alex make.

I was rather unreasonably excited about this idea. This is Margaret Sunday's flower hammer being held up by magnets. Look at all the tools you can keep track of with an idea like this. I'll be looking for those magnets. Thanks Margaret!

Friday, April 19, 2013

Bengt Erikson tapestries at Collected Works

Bengt Erikson has a show of his tapestries at Collected Works in Santa Fe. The show will be up through May. There are seven tapestries hanging.

My favorite pieces are the School House and Old Church--Finland. I love the simple lines and intriguing forms.

Here is a detail of the bottom section of School House. I loved how this shifting 2-warp pattern created texture but blended together from farther away.

There was a similar textural effect on the left side mid-green portion of Old Church--Finland though this time I believe it was pick and pick.

I enjoyed seeing Bengt's work and I recommend a stop to see it. Also look at his beautiful website at www.eriksontapestries.com. Look for Mim's Favorite hanging near the coffee bar. I didn't get a good photo of this piece, but it is a vibrant blue with trees suggested in orange-brown trunks and green tops. I was really inspired by the simplicity and beauty of Bengt's designs. I will have to return to see them again before they come down.

And if you're a local Santa Fean and you've never been to Collected Works, now is the time. It is a great independent bookstore and they even have a coffee shop.

My favorite pieces are the School House and Old Church--Finland. I love the simple lines and intriguing forms.

|

| School House, Bengt Erikson, 57 x 47 inches, wool/cotton/linen/stainless steel |

There was a similar textural effect on the left side mid-green portion of Old Church--Finland though this time I believe it was pick and pick.

|

| Old Church--Finland, Bengt Erikson, 50 x 45 inches, woolcotton |

| ||

| Detail, Old Church--Finland |

| ||

| 15 Ambrose Street, Bengt Erikson, 50 x 47 inches, wool/cotton; Spring--Tacoma, Bengt Erikson, 46 x 38 inches, wool/linen |

I enjoyed seeing Bengt's work and I recommend a stop to see it. Also look at his beautiful website at www.eriksontapestries.com. Look for Mim's Favorite hanging near the coffee bar. I didn't get a good photo of this piece, but it is a vibrant blue with trees suggested in orange-brown trunks and green tops. I was really inspired by the simplicity and beauty of Bengt's designs. I will have to return to see them again before they come down.

And if you're a local Santa Fean and you've never been to Collected Works, now is the time. It is a great independent bookstore and they even have a coffee shop.

Wednesday, April 17, 2013

Taos Fiber Marketplace, this Saturday!

I will be at Taos Fiber Marketplace this Saturday from 9 am to about 4:30 pm demonstrating tapestry. (I reserve the right to leave to either go to the bathroom or get some lunch in case that is when you're looking for me!)

My new postcards arrive tomorrow.

My loom is warped and a demo piece underway.

Unfortunately the car is still filthy and the dog has to go to the kennel. But other than that, we're good to travel!

If you're in Taos this Saturday, April 20th, stop by the convention center and look me up! The website for Taos Fiber Marketplace is HERE.

If not, maybe you should come by Taos Fiber Marketplace this weekend... that is Taos, New Mexico by the way. Taos Convention Center. Check this website for details: http://www.taosfibermarketplace.com/

My new postcards arrive tomorrow.

My loom is warped and a demo piece underway.

Unfortunately the car is still filthy and the dog has to go to the kennel. But other than that, we're good to travel!

If you're in Taos this Saturday, April 20th, stop by the convention center and look me up! The website for Taos Fiber Marketplace is HERE.

If not, maybe you should come by Taos Fiber Marketplace this weekend... that is Taos, New Mexico by the way. Taos Convention Center. Check this website for details: http://www.taosfibermarketplace.com/

Tuesday, April 16, 2013

A new business is born...

Look what I got today after a quick (second) trip to City Hall!

And in the studio considering where to hang it.

And in the studio considering where to hang it.

If you can't read the tiny print, that is a Business License from the City of Santa Fe. Whoop!

Friday, April 12, 2013

Hey, You're Okay.

Thursday is a good day. I get to work in the studio. There is much to be done.

Warping is underway (Harrisville done Tuesday, Mirrix done today).

New ideas are scattered on the design table.

I passed my fire inspection today and will have my business license momentarily.

There are boxes of stuff scattered about for me to constantly trip on. But some of the furniture has arrived and I am somewhat naively assuming that having a place to unpack the boxes into will decrease the tripping hazards.

Emily was in Denver this week and she was kind enough to stop at IKEA and pick up some of the furniture I needed for the studio (and "kind" doesn't actually begin to describe it. She managed to get an 80 pound box of wood that was 5.5 feet long into her Toyota Camry--no small feat). IKEA is one of those places you go into and before you know it, a whole day has disappeared. This is why I didn't go along. I'd still be there in one of those little mock-bedrooms wondering if I could make my bedroom create the same feeling in me and knowing that I can't do it. It was so much easier to send her with a shopping list. She has more self-control.

So we spent some of today putting that furniture together.

The IKEA guys... make sure you have a friend to help you!

At some point I had to go to the hardware store for a rubber mallet because my hands hurt too much from trying to get the parts to go together and the regular hammer chipped the white finish.

And finally I was able to unpack some yarn and figure out whether I have all the colors I need for my workshop in May (see details HERE). I have to dye a few more colors before May 4, but I think I can handle it.

And the challenge of starting an enterprise that has to succeed for several reasons can be really scary.

Fortunately I ran across this TED talk the other night while surfing Netflix.

This is Ze Frank talking about people and care and his Chillout song. I put the song on my iPhone and have been listening to it a lot. You can hear it HERE. Just push the little black triangle on the top of the page. He wrote the song for a woman who emailed him asking for help with her anxiety. He got people to sing along to his track while wearing headphones, record themselves, and then used those tracks to put the song together.

Hey.

You're Okay.

You'll be fine.

Just Breathe.

It helps.

Warping is underway (Harrisville done Tuesday, Mirrix done today).

New ideas are scattered on the design table.

I passed my fire inspection today and will have my business license momentarily.

There are boxes of stuff scattered about for me to constantly trip on. But some of the furniture has arrived and I am somewhat naively assuming that having a place to unpack the boxes into will decrease the tripping hazards.

Emily was in Denver this week and she was kind enough to stop at IKEA and pick up some of the furniture I needed for the studio (and "kind" doesn't actually begin to describe it. She managed to get an 80 pound box of wood that was 5.5 feet long into her Toyota Camry--no small feat). IKEA is one of those places you go into and before you know it, a whole day has disappeared. This is why I didn't go along. I'd still be there in one of those little mock-bedrooms wondering if I could make my bedroom create the same feeling in me and knowing that I can't do it. It was so much easier to send her with a shopping list. She has more self-control.

So we spent some of today putting that furniture together.

The IKEA guys... make sure you have a friend to help you!

At some point I had to go to the hardware store for a rubber mallet because my hands hurt too much from trying to get the parts to go together and the regular hammer chipped the white finish.

And finally I was able to unpack some yarn and figure out whether I have all the colors I need for my workshop in May (see details HERE). I have to dye a few more colors before May 4, but I think I can handle it.

And the challenge of starting an enterprise that has to succeed for several reasons can be really scary.

Fortunately I ran across this TED talk the other night while surfing Netflix.

Hey.

You're Okay.

You'll be fine.

Just Breathe.

It helps.

Tuesday, April 9, 2013

Warping the countermarch loom...

I am happy to say that my Harrisville Designs Rug Loom is now warped. It took about 4 hours longer than I thought it would. It always does. I ran into problems at the end with the tie-up. Apparently after a year and a half in storage and three years of never changing the treadling before that, I have forgotten how to tie it up. After some pondering, I managed to make basket weave with this tie-up:

(where O is a raised shaft and X is a lowered shaft)

Basket weave was nice and all, but not quite the tapestry structure I was looking for. So I tried again with this tie-up (I double the treadle tie-up so that I can reach them easily no matter which side of the loom I am sitting on--you would really only need two treadles):

Bingo. Plain weave.

At one point I was so flustered that I tried to find a diagram online for a countermarch tie-up. The information available is remarkably scare. I will definitely be making a video about this subject before too long. Geez! I am sure there are weavers out there who warp their looms as infrequently as I do (after all, how often do you do a tie-up for your tapestry loom? Only when you take it apart to move it!) and I imagine them all madly googling "countermarch tie-up" and finding nothing much useful.

I went to high school in an age where I did my research in the library with a card catalog and index cards. I copied down information from the books BY HAND. When I was in college I think the card catalog was on computer, but I still was using books (you know, those wads of paper bound together on one edge) for the actual research. By the time I got to graduate school I had a computer into which I typed the information I was copying from, you guessed it, books. But now, I expect to be able to find information like how to tie up a countermarch loom in plain weave (for goodness sake!) on my smart phone in about 5 seconds. The information wasn't there. There was an excellent article by Madelyn van der Hoogt, but it was super hard to read on the tiny screen and the photos were for a different sort of loom than mine and my brain was tired. (The article was from Weaver's magazine, Issue 26 which I believe was printed in 1994.) In the end I dug out Rachel Brown's The Weaving, Spinning, and Dyeing Book. She had a draft for twill for a countermarch loom in there and from that I realized what I had to do. Problem solved. Thanks so much Rachel. You always come through for me.

(The writing on my equipment is courtesy of my grandmother. She didn't have a single piece of weaving equipment that wasn't written on. Mostly it is endearing except perhaps for the first edition weaving books that are underlined within an inch of their lives.)

(where O is a raised shaft and X is a lowered shaft)

Basket weave was nice and all, but not quite the tapestry structure I was looking for. So I tried again with this tie-up (I double the treadle tie-up so that I can reach them easily no matter which side of the loom I am sitting on--you would really only need two treadles):

Bingo. Plain weave.

At one point I was so flustered that I tried to find a diagram online for a countermarch tie-up. The information available is remarkably scare. I will definitely be making a video about this subject before too long. Geez! I am sure there are weavers out there who warp their looms as infrequently as I do (after all, how often do you do a tie-up for your tapestry loom? Only when you take it apart to move it!) and I imagine them all madly googling "countermarch tie-up" and finding nothing much useful.

I went to high school in an age where I did my research in the library with a card catalog and index cards. I copied down information from the books BY HAND. When I was in college I think the card catalog was on computer, but I still was using books (you know, those wads of paper bound together on one edge) for the actual research. By the time I got to graduate school I had a computer into which I typed the information I was copying from, you guessed it, books. But now, I expect to be able to find information like how to tie up a countermarch loom in plain weave (for goodness sake!) on my smart phone in about 5 seconds. The information wasn't there. There was an excellent article by Madelyn van der Hoogt, but it was super hard to read on the tiny screen and the photos were for a different sort of loom than mine and my brain was tired. (The article was from Weaver's magazine, Issue 26 which I believe was printed in 1994.) In the end I dug out Rachel Brown's The Weaving, Spinning, and Dyeing Book. She had a draft for twill for a countermarch loom in there and from that I realized what I had to do. Problem solved. Thanks so much Rachel. You always come through for me.

(The writing on my equipment is courtesy of my grandmother. She didn't have a single piece of weaving equipment that wasn't written on. Mostly it is endearing except perhaps for the first edition weaving books that are underlined within an inch of their lives.)

I am pretty glad to be done with this part of the warping especially. I am 5' 10" tall and when I have to climb inside the loom I do understand the greatness of Cranbrook's extended back space. That sectional back beam isn't a very comfortable back rest.

Saturday, April 6, 2013

Weaving Tapestry in Santa Fe

To get the ball rolling in my new studio, I am going to be teaching my Color Gradation Techniques for Tapestry class May 4, 5, and 7.

Tapestry weaving is the ultimate slow fiber movement. It is also a tradition that is deeply rooted in New Mexico. Santa Fe is the center of that mix of Hispanic, Native, and contemporary tapestry weaving and the result is uniquely New Mexican. Rebecca Mezoff’s tapestry studio in the Second Street art district is a beautiful place to come and learn the art of tapestry or refine skills you already have. The never-ending movement of weft through warp is a wonderful way to express creatively as well as a way to slow down and find some rhythm in life.Color gradation is a striking feature of Rebecca’s work. She loves to teach the blending of color to students with a variety of techniques and her large palette of hand-dyed wool yarn. During this three-day class, students will explore the movement of color in tapestry by weaving a sampler. Different forms of tapestry techniques to move color will be explored and we will create color gradations in all directions in the weaving. Color mixing techniques will be explored and some color theory will be discussed. More advanced students will utilize the techniques to weave a study for a larger piece. Class fee includes use of Rebecca’s hand-dyed tapestry yarn as well as extensive handouts and resources. The class includes Powerpoint presentations as well as the opportunity to create in a working tapestry studio.

This class is offered Saturday, Sunday, and Tuesday giving you a day on Monday to explore the art districts of Santa Fe or experience some of northern New Mexico.

You can find my other class listings (with more coming soon!) and some testimonials about my teaching on my website at http://www.rebeccamezoff.com/teaching/.

The class will be small and we will have a lot of fun!

Class fee is $295 for the three days which includes my standard materials fee for the hand-dyed yarn we will be using. Students will need to bring their own warped loom for the class, either a small floor loom or a table-type tapestry loom (such as a Mirrix).

Please email me if you'd like to sign up for this class. Eventually I'll be rolling out an online sign-up system, but I'm not quite there yet! rebecca (dot) mezoff (at sign) gmail (dot) com

Friday, April 5, 2013

The Harrisville Rug Loom returns!

Look what happened in my new studio today! This pile of hardware

held together a bunch of wood and metal to become this loom.

I went from here:

to here:

In a few hours. I

should mention that I had a lot of help from Emily. I have put this loom

together alone, but for the life of me I don’t know how I did it. You need

about 40 hands to hold all those parts together and still get in the bolts.

The process wasn’t the easiest. The first time I took this

loom apart to move it from my grandparents house to my place in Velarde, NM, I

took a lot of photos. Those photos still exist somewhere in a hard drive that

is undoubtedly buried somewhere in the boxes of stuff not yet unpacked in Santa

Fe. So today I was flying by the seat of my pants to put this baby back

together. I did really well with just about everything (and sometimes I was

just going by where the wood had darkened where it was exposed to the sunshine

to fit pieces together) until I got to the lamm system. Countermarche looms are

a little more complicated than jack looms and my memory failed me when it came

to hooking up the upper and lower lamms. There are a lot of cables and this is

only a 4 harness loom.

I was faced with the myriads of little parts that make up

the rollers over which the cables run from the top lamms.

I just couldn’t work out exactly which way the upper lamm assembly

had to go in to make the whole roller/cable thingy work. I don’t have internet

access yet and didn’t have my computer anyway, so I started digging in the

boxes of books scattered about the studio. I did find the loom manual finally

though unfortunately it was almost entirely text-based (being from the 1980s when my grandfather bought this loom). I sorted out which

cables went where, and at long last the Harrisville is back in working order.

I can’t wait to start warping it.

Monday, April 1, 2013

Welcome to New Mexico, the Land of Enchantment

I have lived much of my life in New Mexico and it wasn’t

that long ago that I left the state for Colorado (534 days to be exact). I

didn’t think I was moving back soon, so I became a Colorado resident (again).

Surprise! It is back to New Mexico for me. Really they should just give me dual

residency, Colorado and New Mexico. It would be so much easier.

Last weekend I moved out of the little farmhouse near

Alamosa, Colorado. I loved the quiet there and watching the cranes, but I will

not miss the skunks! It will forever be known as the skunk house. In fact, I

woke up the other morning in the new condo in Santa Fe, and the first thing I

thought was, boy it smells really nice and clean in here! The underlying

skunkiness apparently just became a new normal during my time in Alamosa.

There was a Budget truck involved. Some crying… a stop at a

gas station in La Jara to get a soda to assuage the crying, and in my fatigue,

I failed to see the BIG no parking sign I parked the truck about 5 feet in

front of. The cop was nice and the tears probably helped me get off with a

warning. The truck got unloaded in Santa Fe and we went back to Alamosa for the

cleaning and the final load of stuff.

I didn’t do a great job packing the moving truck. I

underestimated the stuff in that house and didn’t go high enough. So at the end

I couldn’t find a safe place for my spinning wheel. She had to wait until I

returned with just the car to bring her to the studio. She got her own seat

right next to Cassy the dog.

Between Alamosa and Santa Fe is a mountain called San

Antonio. This mountain has threatened to take my life many times and I am extra

vigilant and say a little blessing for the mountain every time I approach now.

It doesn’t look scary in this photo, but believe me, it can be fierce.

Several times I have been stuck in white-out conditions in

my little Volkswagen Golf on this

stretch of highway and once was saved by a semi who apparently could see where

the road was from his higher vantage point, because I had no idea. All I knew

was that I couldn’t see the road, I knew there was a ditch on either side, and

I couldn’t stop. I could see nothing at all... just white blowing snow. I have

driven through there in the early morning hours to find thousands (I am not

exaggerating for once) of elk standing on the road. They don’t move easily

either. I think it is possible some of the big guys outweigh my car. And once

in May a couple years ago there was a freak snowstorm and I must have hit some

black ice because a gust of wind sent me into a spin and I was suddenly going

down the highway at 60 mph backwards. I didn’t roll. I did end up in the ditch,

but I was fine. I respect the mountain now.

The looms are slowly coming home to the new studio in Santa

Fe. The LeClerc has arrived, the workshop Macomber and Mirrix made it, the

Ladybug spinning wheel survived the car trip thanks to the seatbelt, and the

other looms will arrive this week from their long sojourn in a storage locker.

I can’t wait to tighten their bolts and warp them up. Just imagine the

potential of all those empty looms! I can’t wait.

Subscribe to:

Posts (Atom)