Last week I wrote a post about low-warp looms which you can read

HERE. I use a low-warp loom for much of my weaving and we are partial to what we know. But I have been working hard to

be less prejudiced learn more about high-warp looms and have even used the ones I own more often lately.

High-warp looms are the ones most people think of when you say tapestry. The warp runs mostly perpendicular to the floor and the work sits in front of the weaver much like it would when hung on a wall.

Almost a year ago now I started asking people to send me photos of their tapestry looms and tell me which were their favorites. Here is a compilation of responses with some photos. There are pros and cons to any loom, but clearly there are favorites among the tapestry community. If you want to add your favorite loom to the conversation, please leave a comment below or

Contact me.

Lets start with a couple of the small looms. Most small looms for tapestry are little versions of the bigger high-warp tapestry looms. There are many kinds of small portable looms and a full review of these will have to wait for another day.

Smaller looms that function like a floor loom such as table looms and rigid heddle looms are very poor for tapestry weaving due to small beams, plastic parts, and weak tensioning ability.

Mirrix Looms

UPDATE 5/6/16: Mirrix just rolled out a loom called the "Sam Loom". I do not recommend this loom which is marketed for beginners. It is a basic 12-inch loom minus all the things that make Mirrix great. It has no tray coil and no shedding device. You need these things. Also, I don't advocate the warping method they show with this loom. Just so you know.

Mirrix is a US company that makes wonderful looms with high tensioning ability and a shedding device. The looms come in very tiny sizes for bead weaving. The tapestry looms start at 12 inches wide and go up to 38 inches wide. I own many of these looms and I love them because I get a great tension, they are sturdy, and they are made in the USA. Here is what a few people had to say about their Mirrix looms.

I work exclusively in reverse

soumak in a small scale format and had a problem with tension - the

technique requires drum tight tension. The only loom that works for me

is the Mirrix and at the moment I have a 16" and a 12". They hold the

tension for months at a time, can be used upright or flat and any angle

in between. What more can one want - hard to improve on perfection! --Charles Gee

I

use my Mirrix Zach or Big Sister loom. I love the tensioning device. I

have a small house, so the small foot print works well. --Cheryl R

I

used to often do an overnight for work so purchased a Mirrix Little Guy

that I carried in my overnight bag and wove a number of small projects

on it. --Trish

The

first loom that I purchased was a 32 inch Mirrix. It is okay, but I

found the shed to be too small for my large hands. I modified things so

that I have a bigger shed. I use this loom primarily as a sample loom

at this point, but I've completed several projects on it. --Allen Rumme

I

am new to tapestry weaving. I started with a Mirrix Big Sister, and

have since acquired a Hokett hand loom and a Mirrix Lani. I love the

simplicity of warping all three. --Liz Johnson

|

| Liz Johnson's Mirrix and Hokett tapestry looms |

Archie Brennan-style pipe loom

Archie has made these looms for sale over the years.

The plans are still available on his website with many modifications floating around the internet. They are fairly simple to make and hold an excellent tension. The same principles are often used to make the larger pipe looms and scaffold looms many people use.

|

| A very fancy copper pipe loom made by Jane Hoffman. |

And now let's talk some about the big tapestry looms.

Fireside Cantilever

My

Fireside Loom is wonderful with a worm gear.... I think the worm gear

is great for tapestry. For me the Fireside Loom is outstanding it has

all the features you could want in a high warp loom. --Dee

It probably is the sweetest loom of all, easy action and quite nice to work on. It has a reed but not a beater. --Tommye Scanlin

|

| Tommye Scanlin's Fireside Cantilever tapestry loom |

Ashford Tapestry loom

The large Ashford surprised me. I got it for a steal used and I have to say it is a great loom. I love the circular warping feature it has and it holds very good tension with the tension screws. I also enjoy using leashes more than I thought I would. I did put a Mirrix spring set on top of the loom for warp spacing which has worked out well. The Ashford requires leashes but for the price it is a very good loom. The fact that you can adjust the angle of your weaving on that loom is a great feature for comfort when weaving. --Dee

|

| Ashford tapestry loom |

Glimakra Tapestry Loom

I use an upright Glimakra Tapestry Loom which they no longer make, but Joanne Hall, of Glimakra USA, has been really helpful in providing a copy of the original instructions. Things I like about it are the tensioning, the angle at which I weave and the fact that it has a relatively small 'footprint'. Things I struggle with are how to use the knobs at the top effectively in a small tapestry, setting up leashes and getting an even tension on the warps when using the warp beam. --Matty

I believe the knobs on the top are for bout warping in which allows you to weave a section then untie the warp and twist the weaving, but if you have more details about their purpose, I'd love to hear about it.

|

| Ulrikka Mokdad's Glimakra loom; tapestry by Ulrikka Mokdad |

|

| A student weaving on a Glimakra table-sized tapestry loom (Hi Millie!) |

Shannock

I have seen these large metal looms made by John Shannock frequently over the years. The 24 inch models are popular. I believe he also made four, six, and eight foot versions of this loom.

48" Shannock: This has the absolutely most amazing tension available of any of the looms I have. However, the releasing of warp, when needed, then rolling up on cloth beam is accomplished in a tedious way... not hard, just tedious. Yet the way it's done makes it absolutely impossible to have the warp slipping. Also, the threading of the heddle bars is fiddly and the bars are 24" wide. I've yet to warp it for the full width, being not quite up to using two of the 24" bars side by side to get the full width. I did, however, recently set mine up for 4 heddles and did a double sett with it. --Tommye Scanlin

|

| Tommye Scanlin's Shannock |

My most recent acquisition was a 72 inch Shannock. Yes, I know it's a big loom, but I sort of fell into it and decided that I would never get another chance to buy one like this. This loom is stronger than any of us would ever need. I added a reed holder like Kathy Spoering did, and I modified the shedding devices along the lines of what Lyn Hart did to hers. I also added some hardware to keep the treadles from moving all over the place. They are just on a long tube and slide easily at the slightest provocation. These things make the loom much friendlier to use. I am not completely pleased with the size of the shed at this point and will probably make some additional modifications in this area. One thing that is a bit surprising is that the Shannock, even with its size, is not as imposing as the Tissart. The Tissart actually looks bigger because of the heddle frames and tracks.

On the treddles, I just used some black PVC pipe to make a spacer to keep the treddles separated, and then made some collars for either side. The collars are held in place with nylon screws. These exert enough pressure to hold the collars in place without damaging the tube.

--Allen Rumme

|

| Allen Rumme's Shannock treadles modified so they don't slide. |

|

| 8-foot Shannock of Cindy Dworzak. Note tensioning device at side just below top beam. |

Ruthie

Ruthie--60" It was made by Crisp and hasn't been made since the 1980s. However, the Fireside Traditional tapestry loom is based upon the design of the Ruthie, from what I've been told. It has a beater that's counterweighted. It has three sets of two treadles each. --Tommye Scanlin

|

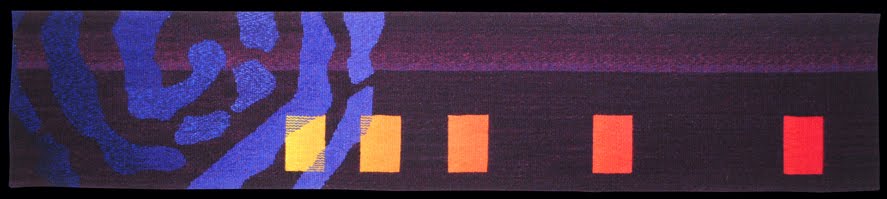

| Tommye Scanlin's Ruthie loom with tapestry by Tommye |

Tissart, made by Leclerc

Tissart--45" Modifications I've made to it are adding two more treadle sets (it now has three sets of two each); having John Shannock custom make a top beam (to correct some warping I had through the years with the beam); and I C-clamp the beater up to its highest point since I build shapes rather than working from selvedge to selvedge. (I still find having the reed in the beater useful, though). This was my first upright tapestry loom. The Tissart hasn't been made by Leclerc in many years. --Tommye Scanlin

|

| Tommye Scanlin cutting a piece off her 45" Tissart |

My workhorse loom is a 60" Leclerc Tissart tapestry loom. I use it primarily for my rugs, but since my rugs have many tapestry like elements I'll say that I use it for tapestry. This loom requires some strengthening to be usable for rugs and tapestry, as the top and bottom beams flex quite a bit under the kind of tension that I need. I have strengthened both with heavy, 2 inch angle iron. This improves the situation quite a bit. The smaller Tissart looms are probably a little sturdier given that these beams are shorter. The counterbalance shedding device works well, and the shed is plenty large. --Allen Rumme

|

| Allen Rumme's Tissart |

Leclerc Gobelin loom

There's one photo of three looms together... one is the Shannock (on the right), the middle is the Fireside Cantilever, and the left hand side is the Leclerc loom that's sort of like the Gobelin style and sort of like the Tissart... the one that supposedly came from Black Mountain College. It has harnesses, a beater and treadles.

Tommye's further description of the Leclerc: And now I've got another Leclerc sort of hybrid, kind of like the Gobelin style you have (and I once had) and kind of like the Tissart. Apparently it wasn't a production model of loom but I can't find more about it's history. Supposedly came from a "famous" weaver at Black Mountain College (surely not Anni Albers... maybe, though, Trude Guermonprez?). That loom I got from someone who'd gotten it from Warren Wilson College 20+ yrs ago, and WWC had gotten it from BMC. Anyway... history somewhere lost in the web of time! --Tommye Scanlin

(Does anyone know anything about Tommye's loom? It is like a murder mystery novel but with loom origin... and what it if WAS Anni's or Trudi's? Would that explain Tommye's astounding abilities in tapestry? No. Likely that comes from all her hard work. Make sure to look at Tommye's blog for continuous useful information about tapestry.

http://tapestry13.blogspot.com/)

|

| Looms left to right: Leclerc, Fireside Cantilever, Shannock. Tommye Scanlin |

My Leclerc is the old Gobelin style loom. Mine doesn't have the shedding mechanism and I use leashes. You can buy a shedding mechanism that uses treadles. You can't see in the photo below, but there are tensioning screws on the sliding wooden bar that the bottom beam rests in. I can achieve a very high tension on this loom. Advancing the warp means rolling the top and bottom beam which works on a pall and ratchet system. It is a sturdy and uncomplicated loom.

|

| Rebecca Mezoff's Leclerc Gobelin tapestry loom |

Brittany

This loom was made in the 70s in California by the same people who make Brittany knitting needles/ crochet hooks. It is solid walnut with a "rolling" heddle. In the first pic you can see the frame which can hold a warp 17.5 inches wide and 70" around. It came with some batons, a tension rod, some skinny dowels, and the rolling heddle (which you can see propped on the bottom of the frame and in the close-up 2nd picture. The slots that are shorter on the front of the heddle are longer on the back and vice versa for the long slots on the front. After you warp the loom, you remove the skinny dowel in the heddle and place the warps in the slots. The warps go in opposing slants; when you 'roll' the heddle forward it opens one shed, and when you 'roll' it backward it opens the other. --Kristin Merritt

|

| Brittany Tapestry Loom of Kristin Merritt |

|

| Brittany Tapestry loom, detail |

Scaffold Looms

Looms are actually not that difficult to make according to the many fans of scaffold looms.

|

| Dorothy Clews scaffold loom |

Many of our most revered tapestry artists use them. Here are two:

|

| Susan Martin Maffei working at the top of her scaffold loom |

And Archie Brennan. If you haven't watched this YouTube video, there are several examples of scaffold looms in it.

https://www.youtube.com/watch?v=Ne6WI5uozQs

And for a stunning video demonstrating high warp weaving from the Dovecot in Scotland, please give this video some time. Click

HERE to see it on Vimeo or watch below.

And I would just like to end with this excellent story told by Tommye Scanlin:

And this is what Archie [Brennan] had to say to a group of us in a workshop once when we were sitting around talking about what was the "best" tapestry loom to have. This was afternoon discussion time, we were sitting in a circle of chairs, Archie and Susan [Martin Maffei] among the students. The discussion began with a question from one of us about what would be the best tapestry loom to have. And then we all began to describe what we had, features of the looms we like, etc. The dialogue went on for several minutes. Finally someone asked Archie for his opinion... he settled back in his chair, arms crossed over his chest, said: "The quality of the weaving starts with the weaver and moves out...."